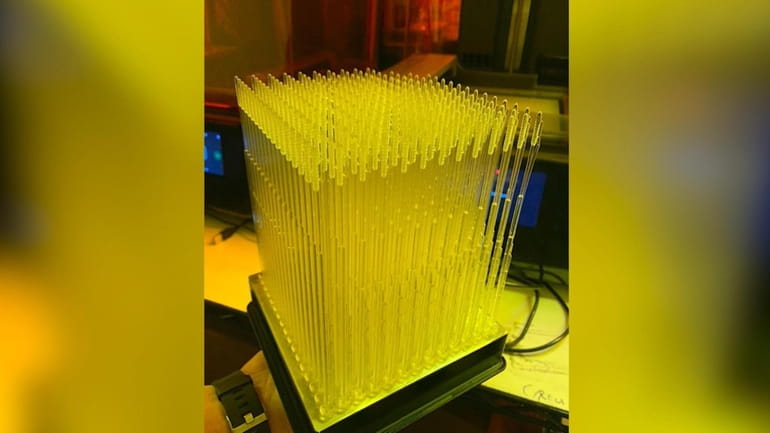

Northwell Health 3-D prints nasal swabs for coronavirus testing

Northwell Health says it has found a way to 3-D print about 1,500 nasal swabs daily for COVID-19 testing.

Hospitals and medical offices nationwide have said a lack of nasopharyngeal swabs has led them to severely limit whom they test. At many clinics, only the most at-risk to the coronavirus get tested. That would include people over the age of 60, and patients with underlying medical conditions.

Nasopharyngeal swabs are required for the coronavirus tests because they are able to get to the nasopharynx, which is behind your nose and above your throat. A successful swab design would need to reach that area and then be able to be pulled back out through the nostril without losing the sample. The swabs are about 6 inches long.

Northwell said it teamed up with the University of South Florida in Tampa, and Formlabs in Somerville, Massachusetts, to create the design.

It took about one week for the research team to pinpoint and test an effective 3-D printed design, said Dr. Todd Goldstein, director of design and innovation at Northwell and researcher at the Feinstein Institutes for Medical Research.

Manhasset-based Feinstein is Northwell's medical research arm.

"We had to find a happy medium in the design, so we didn't irritate a patient," Goldstein said. "If it's too smooth, it doesn't grab a sample. But if we make it too rough, the patient ends up with a nosebleed."

Goldstein said unlike the current swab supply, the printed versions are made out of the plastic used to make surgical guides, such as dental implant guides. He said since elective surgeries are on hold, the material and printers are available.

Northwell has eight machines printing the swabs daily, he said.

Northwell said it would make their protocols on how to create the swabs public online to help other institutions around the world replicate the swabs for their own use.

"The best way to self-quarantine and flatten the curve is to be able to test everyone, so we can tell them to stay home," Goldstein said. "But we can't test everyone if there is a shortage, so we are going to open-source this."

Stony Brook University has also turned to 3-D printing to help with shortages.

Faculty and students there are using 3-D printing to make 40 to 45 protective face shields a day, the university’s interim president, Michael Bernstein, said in a Facebook Live event Wednesday afternoon.

The face shields being used by medical staff are designed by iCREATE, a program under the Division of Information Technology at Stony Brook University.

Certain parts of these face shields are designed to be replaceable so that medical personnel can change them out, allowing for a more sanitized product, Stony Brook University Hospital said.

iCREATE has supplies to make about 800 face shields and is currently in the process of procuring enough supplies to make up to 5,000 products.